|

|||||||||||||||||||||||||||||||||||||

|

|

Passive-House 3 Report | ||||||||||||||||||||||||||||||||||||

|

PASSIVE HOUSE REPORT 3 PASSIVE HOUSES AND PASSIVE HOUSES IN THE MEDITERRANEAN CLIMATE EU-Project “CLAY” BASIC ELEMENTS PART 1 A modern house loses the thermal energy in three ways – through the building envelope (outer walls, roof and foundation), through its windows and through ventilation. The following basic elements are required to construct a passive house to lose minimum energy. Aim of the “BASIC ELEMENTS” is to reduce the building`s annual demand for space heating to 15 kWh/(m2a). SUPER-INSULATION In a Passive Home the whole building envelope has an exellent thermal insulation without thermal bridges. The envelope consists of all parts of the construction, which separate the indoor climate from the outdoor climate. During hot summers, the high thermal insulation is also a protection against summer heat (and for the Mediterranean climate). U-values should be around 0,10 – 0,15 W/(m2K) for the component part. The U-value points out the energy stream of a component part in watt in 1 hour thru 1 square metre and the temperature difference between inside and outside is 1 degree Kelvin. The whole building envelope has to be built with thick insulation. Each component part of the building envelope must have these U-values around 0,10 – 0,15 W/(m2K)! Think about the principle like a vacuum flask. Only the windows and outside doors have other U-values. It should be one system of a manufacturing firm. The insulation can be “Styropor” or stone wool or also other insulation.

Fig. 1: Picture Friedl, Architect © Outer wall in a timber house with super insulation No 1: 50-70 mm inside installation level: - inside wallfacing - installation / insulation / wood Airtight inside woodboard (airtightness with adhesive tape on gaps and board piles) 350-450 mm super-insulation with * timber trus(s) joist. Outer windtight wood fibre board with wallfacing *One manufacture: www.trusjoist.com

Fig. 2: Picture Friedl, Architect © (no insulation inside) Slab to the ground in a timber house with super insulation Under the regular floor construction you should build a similar timber house outer wall (No.2) construction to reach the low U-values.

Fig. 3: Picture Friedl, Architect © Roof in a timber house with super insulation The roof construction can be built similar to the timber house outer wall construction. Fig 4: The insulation and the inside airtight woodboard to the roof is still missing. On the outer walls you see a part of the inside installation level.

Fig. 4: Picture Friedl, Architect © (no insulation inside) Slab to the ground in a stone house with super insulation. Under the concrete foundation should be 200-300 mm super-insulation (no gaps). Warning: You need a stress analysis for the capacity of the insulation under the concrete.

Fig. 5: www.isoquick.de All construction methods can be used in Passive Houses and have been tested successfully: - masonry construction - lightweight construction - prefabricated elements - insulating concrete formwork construction - steel construction - and other combinations of the methods above (see Fig. 6) Combination of the construction method: - steel construction - timber trus(s) joist The author of this report developed the construction on the roof.

Fig. 6: Picture Friedl, Architect © B: CONSTRUCTION WITHOUT THERMAL BRIDGES All Passive Houses must be constructed thermal bridge free. Thermal bridge free are constructions close or equal to zero (Ψ< 0,01 W/mK). The component parts should be connected thermal bridge free. Of course thermal bridges may lead to increase heat losses, even in a Passive House. You will find thermal bridge free constructions in the bibliography of the passive house institute. For other construction you need a computer software for the thermal (free) bridges. In some types, manufacturers give you some information about the thermal bridges. When the construction is not thermal bridge free, you have to calculate the thermal bridges with the Passive House Software (PHPP). Seldom are regular constructions thermal bridge free ! Example for optimized thermal bridges To reduce the thermal bridge connection of the steel support to the concrete slab, build a timber part in between. The german manufacturer “Schöck / www.Schoeck.de” has similar parts, but in my opinion the Schöck thermal bridge free construction is no better than this timber connection. Fig.7: The author of this report developed the construction for a Passive House.

Fig. 7: Picture Friedl, Architect © C: AIRTIGHT BUILDING ENVELOPE The external envelope of the Passive House should be as airtight as possible. Usually the airtight envelope is constructed inside of the external envelope. This requires careful workmanship of details. The remaining air leakage rates were measured by means of building airtightness tests. In Germany we call the pressurization test “Blower-Door-Test”. leakage rates: n50-values Regular older houses n50 4 - 10 h-1 Regular German new standard houses with no ventilation n50 < 3 h-1 Regular German new standard houses with ventilation: n50 < 1,5 h-1 Passive Houses: n50 < 0,6 h-1 (In practice values between 0,2 – 0,6 h-1 have been measured in Passive Houses) Fig.8: mention of source Friedl, Architect © The leakage rates in the external envelope should be as low as possible. In a Passive House the polluted air is removed by the ventilation system with efficient heat recovery.

For example in a passive single house, the sum of all leakages and gaps should be smaller than 10 x 10 cm to reach n50 < 0,6 h-1. Older Houses are so airtight that infiltration alone is inadequate to assure acceptable indoor air quality and moist room air exfiltration caused damages in the construction. A key principle is maintaining “an undisturbed, airtight envelope”, which can be recognized by the “rule of the red line”.

Fig. 9: Pressurization test “Blower-Door-Test”

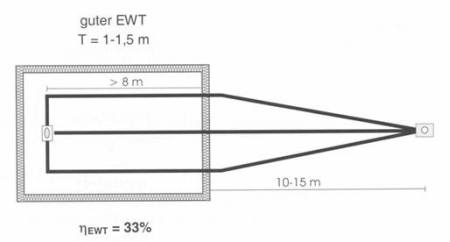

Fig. 10: Airtightness D: SUBSOIL HEAT EXCHANGER The subsoil heat exchanger is outside of the building. It is an easy opportunity to save energy, by using the subsoil energy. In wintertime, fresh air is subsoil preheated to 8°C before the air flows into the mechanical ventilation system. In summertime, fresh air is precooled from the subsoil. Length of the subsoil heat exchanger 40-60 m, about 1,5 m deep in the ground.

Fig. 11: Mention of source passive house institut The reason is that the ground in winter has a higher temperature than outdoor air, and during the summer a lower temperature than outdoor air.

Fresh air suction tower.

A Passive House from the author werner friedl built in 2005 in Hörgertshausen / Germany In the next Passive House report No. 4 you can read many more details about the following part II of the basic elements. In particular for:

Werner Friedl Architekt Mention of sources used: - Website: Deutsches Passivhausinstitut, Darmstadt (www.passiv.de) - Cepheus Proposal Summary, Deutsches Passivhausinstitut, Darmstadt - Cepheus ECEEE, Jürgen Schnieders, Deutsches Passivhausinstitut, Darmstadt - Cepheus-Projektinformationen Nr. 38, Abschlussbericht Juli 2001, Deutsches Passivhausinstitut, Darmstadt, (Thermie-Program of EU BU/0127/97) - Webseite TrusJoist / USA - Webseite Rockwool / Germany Thanks to Tom Lappas, Las Vegas, USA for proofreading. | ||||||||||||||||||||||||||||||||||||